SESHA

SESHA  SESHA

SESHA  SESHA

SESHA

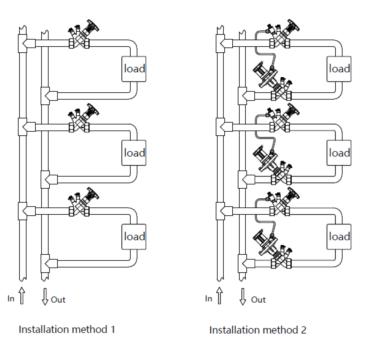

Isetshenziselwa ukulawula okusethiwe ngaphambili kokugeleza kwamapayipi, lolu chungechunge lwemikhiqizo lusetshenziswa kakhulu ukuxazulula inkinga yokungalingani kwe-hydraulic kunethiwekhi yokudlulisela nokusabalalisa uketshezi.Ngokusho kokuhlelwa kwesistimu, kunqunywa ukuthi ukunikezwa kwamanzi kwegatsha kuhlala njalo ngaphansi kwesisekelo sokuvuleka okuhlukene nokuhluka kwengcindezi.

I-valve yokulinganisa ye-KMF iletha ukusebenza okunembile kwe-hydronic kuhlelo oluhlaba umxhwele lwezinhlelo zokusebenza.Ifaneleka kahle ukuthi isetshenziswe ohlangothini lwesibili kumasistimu okushisa nawokupholisa, namasistimu wamanzi ampompi.

| DN | I-DN15-DN50 | I-DN50-DN300 |

| Umzimba | Ithusi | I-Nodular cast iron |

| Izimpawu | I-EPDM | I-EPDM |

| Spool | Ithusi | Ithusi |

| Maphakathi | Amanzi ashisayo anezinga lokushisa eliphansi, amanzi ashisayo aphakathi nendawo, amanzi abandayo, amanzi ane-antifreeze Okutuswayo: Ukwelashwa kwamanzi |

| Izinga lokushisa elimaphakathi | -10 ~ 110℃ |

| Isigaba se-PN | I-PN16 |

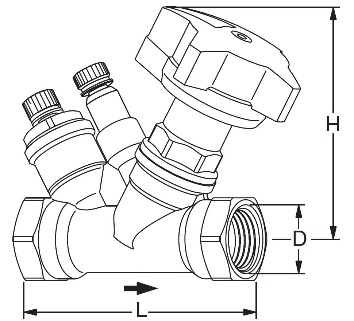

| Inombolo yomkhiqizo | DN | Ukuxhumana | PN | L | H |  | |

| 6067.15 | 15 | 1/2 in | Uchungechunge lwangaphakathi (BSP) | I-PN16 | 80 | 114 | |

| 6067.20 | 20 | 3/4 in | 85 | 116 | |||

| 6067.25 | 25 | 1 phakathi | 98 | 119 | |||

| 6067.32 | 32 | 11/4 in | 110 | 136 | |||

| 6067.40 | 40 | 11/2 in | 120 | 138 | |||

| 6067.50 | 50 | 2in | 150 | 148 | |||

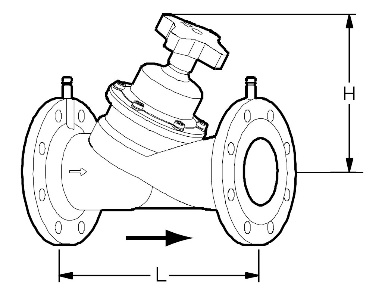

| 6068.65 | 65 | I-Flanged(ISO7005-2/ GB 17241.6) | 290 | 285 |  | ||

| 6068.80 | 80 | 310 | 324 | ||||

| 6068.100 | 100 | 350 | 355 | ||||

| 6068.125 | 125 | 400 | 410 | ||||

| 6068.150 | 150 | 480 | 477 | ||||

| 6068.200 | 200 | 600 | 613 | ||||

| 6068.250 | 250 | 730 | 740 | ||||

| 6068.300 | 300 | 850 | 828 | ||||

| 6068.350 | 350 | 980 | 970 | ||||

| 6068.400 | 400 | 1100 | 1100 | ||||

| Inombolo yomkhiqizo | DN | Inani lamajika | ||||||||||

| 0.25 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | ||

| 6067.15 | I-DN15 | 0.21 | 0.35 | 0.48 | 0.55 | 0.74 | 0.97 | 1.36 | 1.72 | 2.06 | 2.36 | 2.72 |

| 6067.20 | I-DN20 | 0.34 | 0.51 | 0.71 | 0.92 | 1.15 | 1.35 | 1.62 | 2.05 | 2.60 | 3.13 | 3.67 |

| 6067.25 | DN25 | 0.55 | 0.94 | 1.54 | 2.07 | 2.57 | 3.10 | 3.70 | 4.43 | 5.5 | 5.94 | 6.73 |

| 6067.32 | I-DN32 | 0.59 | 1.04 | 2.05 | 2.91 | 4.03 | 5.10 | 6.02 | 6.86 | 7.65 | 8.63 | 9.70 |

| 6067.40 | I-DN40 | 1.22 | 2.65 | 4.14 | 5.75 | 7.35 | 8.72 | 10.03 | 11.22 | 12.35 | 13.83 | 15.25 |

| 6067.50 | I-DN50 | - | 2.70 | 5.05 | 7.15 | 9.15 | 11.66 | 14.22 | 16.35 | 18.52 | 20.72 | 22.95 |

| Inombolo yomkhiqizo | DN | Inani lamajika | ||||||||||

| 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | |||

| 6067.15 | I-DN15 | 3.05 | 3.42 | 3.70 | 3.90 | - | - | - | - | - | - | - |

| 6067.20 | I-DN20 | 4.25 | 4.90 | 5.45 | 5.70 | - | - | - | - | - | - | - |

| 6067.25 | DN25 | 7.33 | 7.90 | 8.42 | 8.90 | - | - | - | - | - | - | - |

| 6067.32 | I-DN32 | 10.72 | 11.72 | 12.80 | 13.90 | 15.04 | 16.14 | 17.15 | 18.16 | 18.90 | 19.42 | - |

| 6067.40 | I-DN40 | 17.36 | 19.44 | 20.96 | 22.43 | 23.62 | 24.80 | 25.42 | 26.07 | 26.82 | 27.50 | - |

| 6067.50 | I-DN50 | 24.52 | 26.07 | 27.74 | 29.40 | 31.12 | 32.75 | 34.72 | 36.70 | 37.96 | 38.80 | - |

| Inani lamajika | Inombolo yomkhiqizo | |||||||||

| 6068.65 | 6068.80 | 6068.100 | 6068.125 | 6068.150 | 6068.200 | 6068.250 | 6068.300 | 6068.350 | 6068.400 | |

| I-DN 65 | I-DN80 | I-DN 100 | Idatha ye-DN125 | Idatha ye-DN150 | I-DN 200 | I-DN 250 | I-DN 300 | Idatha ye-DN350 | I-DN 400 | |

| 0.5 | 1.8 | 2 | 2.6 | 5.4 | 6.6 | - | - | - | - | - |

| 1 | 3.4 | 4 | 6 | 10.4 | 12 | - | - | - | - | - |

| 1.5 | 4.8 | 6 | 9 | 15.4 | 22 | - | - | - | - | - |

| 2 | 6.6 | 8 | 11.5 | 21.5 | 40 | 40 | 90 | - | - | - |

| 2.5 | 9.3 | 11 | 16 | 27 | 65 | 50 | 110 | - | - | - |

| 3 | 16.3 | 14 | 26 | 36 | 100 | 65 | 140 | 150 | 109 | 125 |

| 3.5 | 25.5 | 19.6 | 44 | 55 | 135 | 90 | 195 | 230 | 129 | 148 |

| 4 | 35.4 | 29 | 63 | 83 | 169 | 120 | 255 | 300 | 148 | 171 |

| 4.5 | 44.5 | 41 | 80 | 114 | 207 | 165 | 320 | 370 | 170 | 208 |

| 5 | 52 | 55 | 98 | 141 | 242 | 225 | 385 | 450 | 207 | 264 |

| 5.5 | 60.6 | 68 | 115 | 167 | 279 | 285 | 445 | 535 | 254 | 326 |

| 6 | 66 | 80 | 132 | 197 | 312 | 340 | 500 | 620 | 302 | 386 |

| 6.5 | 73 | 92 | 145 | 220 | 340 | 400 | 545 | 690 | 352 | 449 |

| 7 | 77 | 103 | 159 | 249 | 367 | 435 | 590 | 750 | 404 | 515 |

| 7.5 | 80.6 | 113 | 175 | 276 | 391 | 470 | 660 | 815 | 471 | 590 |

| 8 | 85 | 120 | 190 | 300 | 420 | 515 | 725 | 890 | 556 | 680 |

| 9 | - | - | - | - | - | 595 | 820 | 970 | 784 | 890 |

| 10 | - | - | - | - | - | 650 | 940 | 1040 | 957 | 1140 |

| 11 | - | - | - | - | - | 710 | 1050 | 1120 | 1100 | 1250 |

| 12 | - | - | - | - | - | 765 | 1185 | 1200 | 1260 | 1400 |

| 13 | - | - | - | - | - | - | - | 1320 | 1420 | 1560 |

| 14 | - | - | - | - | - | - | - | 1370 | 1610 | 1730 |

| 15 | - | - | - | - | - | - | - | 1400 | 1760 | 1940 |

| 16 | - | - | - | - | - | - | - | 1450 | 1870 | 2140 |

| 17 | - | - | - | - | - | - | - | - | 1960 | 2280 |

| 18 | - | - | - | - | - | - | - | - | 2040 | 2410 |

| 19 | - | - | - | - | - | - | - | - | 2130 | 2530 |

| 20 | - | - | - | - | - | - | - | - | 2200 | 2630 |

| 21 | - | - | - | - | - | - | - | - | - | 2710 |

| 22 | - | - | - | - | - | - | - | - | - | 2780 |

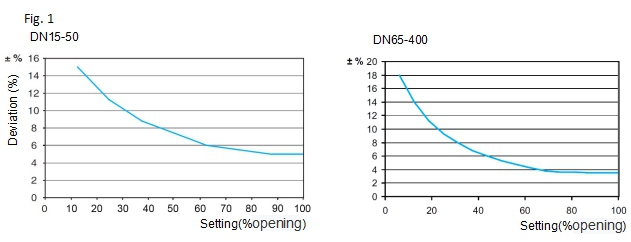

Indawo enguziro ilinganiselwe futhi akufanele ishintshwe.

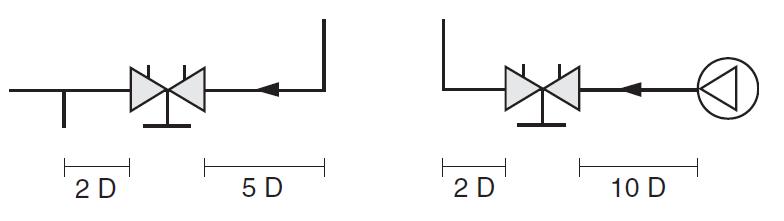

Ijika (Fig. 1) livumelekile kuma-valve anezinsimbi ezivamile zamapayipi (Fig.2).Zama futhi ukugwema ukufaka ompompi namaphampu, ngokushesha ngaphambi kwe-valve.

Fig.2

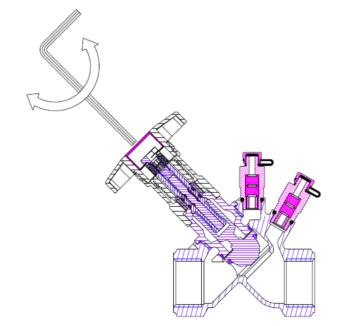

Lungisa isikali sesondo lesandla ngokuya ngezidingo zokuklama.

Imishini yokukhipha umoya kufanele ifakwe kumapayipi esistimu, futhi isistimu ingaqukatha umoya, okungase kubangele ukuvinjelwa kwemidiya, ukwehluleka komsebenzi wokulungisa, noma umsindo omkhulu;

Kunconywa ukwengeza isihlungi noma ukuhlanza ipayipi endaweni yokungena kwamanzi ye-valve ukugwema izinhlayiya ezinkulu zokungcola ezivimbela isici sokulawula i-valve;

Naka ukuvikelwa kwembobo yokuthola, uma ithintwa noma ikhubazekile, izodala ukuvuza noma ukulungisa okunzima esikhathini esizayo.

Lungisa isikali sesondo lesandla ngokuya ngezidingo zokuklama.

Le valve inomsebenzi wokusetha kuqala izinga lokugeleza eliphezulu.Sebenzisa i-wrench ene-hexagonal ukuze uzungezise umkhawulo womkhawulo wokuvula ngokuhambisana newashi, ukuze umkhawulo wokuvuleka kwe-valve, futhi ukugcinwa kwesistimu okulandelayo ngeke kudinge ukususa iphutha.

I-valve yebhalansi ingasetshenziswa yodwa ukulawula ukugeleza kwesistimu, noma ingasetshenziswa ngokuhambisana ne-valve yokucindezela okuhlukile.Lapho i-valve ifakiwe, isiqondiso sokugeleza kwamanzi kufanele sihambisane nesiqondiso somcibisholo ku-valve.Ukuze uqinisekise ukunemba kwesilinganiso, sicela uqinisekise ukuthi kunezigaba zamapayipi eziqondile ngaphambi nangemuva kwevalvu(Fig.2)