SEARCH

SEARCH

SEARCH

SEARCH

SEARCH

SEARCH

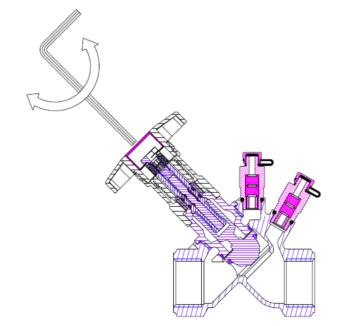

Used for pre-set control of pipeline flow, this series of products are mainly used to solve the problem of hydraulic imbalance in the fluid transmission and distribution network. According to the system design, it is determined that the branch water supply is constant under the premise of different openings and pressure differences.

The KMF balancing valve delivers accurate hydronic performance in an impressive range of applications. Ideally suited for use on the secondary side in heating and cooling systems, and tap water systems.

| DN | DN15-DN50 | DN50-DN300 |

| Body | Brass | Nodular cast iron |

| Seals | EPDM | EPDM |

| Spool | Brass | Brass |

| Medium | Low-temperature hot water,medium temperature hot water,chilled water, water with antifreeze

Recommendation: Water treatment |

| Medium temperature | -10~110℃ |

| PN class | PN16 |

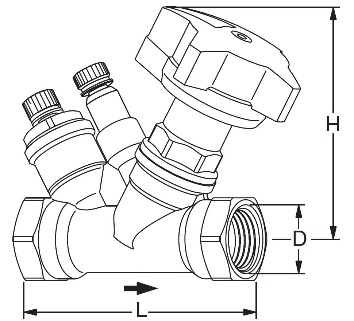

| Product number | DN | Connections | PN | L | H |  |

|

| 6067.15 | 15 | 1/2 in | Internal thread (BSP) | PN16 | 80 | 114 | |

| 6067.20 | 20 | 3/4 in | 85 | 116 | |||

| 6067.25 | 25 | 1 in | 98 | 119 | |||

| 6067.32 | 32 | 11/4 in | 110 | 136 | |||

| 6067.40 | 40 | 11/2 in | 120 | 138 | |||

| 6067.50 | 50 | 2in | 150 | 148 | |||

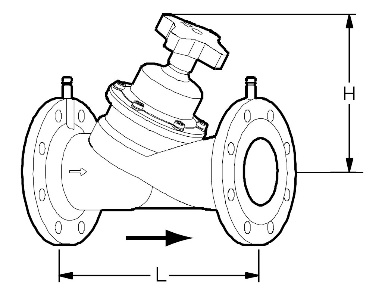

| 6068.65 | 65 | Flanged(ISO7005-2/ GB 17241.6) | 290 | 285 |  |

||

| 6068.80 | 80 | 310 | 324 | ||||

| 6068.100 | 100 | 350 | 355 | ||||

| 6068.125 | 125 | 400 | 410 | ||||

| 6068.150 | 150 | 480 | 477 | ||||

| 6068.200 | 200 | 600 | 613 | ||||

| 6068.250 | 250 | 730 | 740 | ||||

| 6068.300 | 300 | 850 | 828 | ||||

| 6068.350 | 350 | 980 | 970 | ||||

| 6068.400 | 400 | 1100 | 1100 | ||||

| Product number | DN | No of turns | ||||||||||

| 0.25 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | ||

| 6067.15 | DN15 | 0.21 | 0.35 | 0.48 | 0.55 | 0.74 | 0.97 | 1.36 | 1.72 | 2.06 | 2.36 | 2.72 |

| 6067.20 | DN20 | 0.34 | 0.51 | 0.71 | 0.92 | 1.15 | 1.35 | 1.62 | 2.05 | 2.60 | 3.13 | 3.67 |

| 6067.25 | DN25 | 0.55 | 0.94 | 1.54 | 2.07 | 2.57 | 3.10 | 3.70 | 4.43 | 5.5 | 5.94 | 6.73 |

| 6067.32 | DN32 | 0.59 | 1.04 | 2.05 | 2.91 | 4.03 | 5.10 | 6.02 | 6.86 | 7.65 | 8.63 | 9.70 |

| 6067.40 | DN40 | 1.22 | 2.65 | 4.14 | 5.75 | 7.35 | 8.72 | 10.03 | 11.22 | 12.35 | 13.83 | 15.25 |

| 6067.50 | DN50 | - | 2.70 | 5.05 | 7.15 | 9.15 | 11.66 | 14.22 | 16.35 | 18.52 | 20.72 | 22.95 |

| Product number | DN | No of turns | ||||||||||

| 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | |||

| 6067.15 | DN15 | 3.05 | 3.42 | 3.70 | 3.90 | - | - | - | - | - | - | - |

| 6067.20 | DN20 | 4.25 | 4.90 | 5.45 | 5.70 | - | - | - | - | - | - | - |

| 6067.25 | DN25 | 7.33 | 7.90 | 8.42 | 8.90 | - | - | - | - | - | - | - |

| 6067.32 | DN32 | 10.72 | 11.72 | 12.80 | 13.90 | 15.04 | 16.14 | 17.15 | 18.16 | 18.90 | 19.42 | - |

| 6067.40 | DN40 | 17.36 | 19.44 | 20.96 | 22.43 | 23.62 | 24.80 | 25.42 | 26.07 | 26.82 | 27.50 | - |

| 6067.50 | DN50 | 24.52 | 26.07 | 27.74 | 29.40 | 31.12 | 32.75 | 34.72 | 36.70 | 37.96 | 38.80 | - |

| No of turns | Product number | |||||||||

| 6068.65 | 6068.80 | 6068.100 | 6068.125 | 6068.150 | 6068.200 | 6068.250 | 6068.300 | 6068.350 | 6068.400 | |

| DN 65 | DN 80 | DN 100 | DN 125 | DN 150 | DN 200 | DN 250 | DN 300 | DN 350 | DN 400 | |

| 0.5 | 1.8 | 2 | 2.6 | 5.4 | 6.6 | - | - | - | - | - |

| 1 | 3.4 | 4 | 6 | 10.4 | 12 | - | - | - | - | - |

| 1.5 | 4.8 | 6 | 9 | 15.4 | 22 | - | - | - | - | - |

| 2 | 6.6 | 8 | 11.5 | 21.5 | 40 | 40 | 90 | - | - | - |

| 2.5 | 9.3 | 11 | 16 | 27 | 65 | 50 | 110 | - | - | - |

| 3 | 16.3 | 14 | 26 | 36 | 100 | 65 | 140 | 150 | 109 | 125 |

| 3.5 | 25.5 | 19.6 | 44 | 55 | 135 | 90 | 195 | 230 | 129 | 148 |

| 4 | 35.4 | 29 | 63 | 83 | 169 | 120 | 255 | 300 | 148 | 171 |

| 4.5 | 44.5 | 41 | 80 | 114 | 207 | 165 | 320 | 370 | 170 | 208 |

| 5 | 52 | 55 | 98 | 141 | 242 | 225 | 385 | 450 | 207 | 264 |

| 5.5 | 60.6 | 68 | 115 | 167 | 279 | 285 | 445 | 535 | 254 | 326 |

| 6 | 66 | 80 | 132 | 197 | 312 | 340 | 500 | 620 | 302 | 386 |

| 6.5 | 73 | 92 | 145 | 220 | 340 | 400 | 545 | 690 | 352 | 449 |

| 7 | 77 | 103 | 159 | 249 | 367 | 435 | 590 | 750 | 404 | 515 |

| 7.5 | 80.6 | 113 | 175 | 276 | 391 | 470 | 660 | 815 | 471 | 590 |

| 8 | 85 | 120 | 190 | 300 | 420 | 515 | 725 | 890 | 556 | 680 |

| 9 | - | - | - | - | - | 595 | 820 | 970 | 784 | 890 |

| 10 | - | - | - | - | - | 650 | 940 | 1040 | 957 | 1140 |

| 11 | - | - | - | - | - | 710 | 1050 | 1120 | 1100 | 1250 |

| 12 | - | - | - | - | - | 765 | 1185 | 1200 | 1260 | 1400 |

| 13 | - | - | - | - | - | - | - | 1320 | 1420 | 1560 |

| 14 | - | - | - | - | - | - | - | 1370 | 1610 | 1730 |

| 15 | - | - | - | - | - | - | - | 1400 | 1760 | 1940 |

| 16 | - | - | - | - | - | - | - | 1450 | 1870 | 2140 |

| 17 | - | - | - | - | - | - | - | - | 1960 | 2280 |

| 18 | - | - | - | - | - | - | - | - | 2040 | 2410 |

| 19 | - | - | - | - | - | - | - | - | 2130 | 2530 |

| 20 | - | - | - | - | - | - | - | - | 2200 | 2630 |

| 21 | - | - | - | - | - | - | - | - | - | 2710 |

| 22 | - | - | - | - | - | - | - | - | - | 2780 |

The zero position is calibrated and must not be changed.

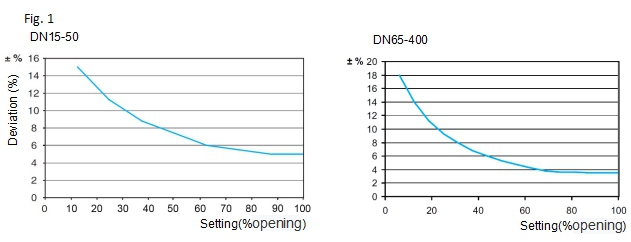

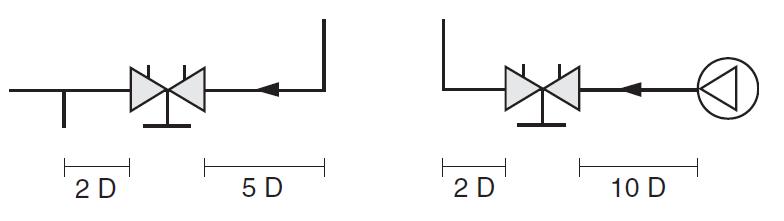

The curve (Fig. 1) is valid for valves with normal pipe fittings (Fig.2). Try also to avoid mounting taps and pumps, immediately before the valve.

Fig.2

Adjust the scale of the handwheel according to the design requirements.

Exhaust devices should be installed in the system piping, and the system can contain air, which may cause media blockage, failure of the adjustment function, or excessive noise;

It is recommended to add a filter or clean the pipeline at the water inlet of the valve to avoid large particles of impurities blocking the valve control element;

Pay attention to the protection of the detection hole, if it is touched or deformed, it will cause leakage or difficult maintenance in the future.

Adjust the scale of the handwheel according to the design requirements.

This valve has the function of presetting the maximum flow rate. Use a hexagonal wrench to rotate the maximum opening limit core clockwise, so that the maximum opening of the valve can be limited, and subsequent system maintenance will not require debugging.

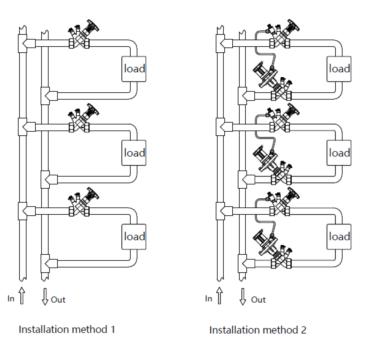

The balance valve can be used alone to control the flow of the system, or it can be used in conjunction with the differential pressure valve. When the valve is installed, the water flow direction must be consistent with the direction of the arrow on the valve. In order to ensure the measurement accuracy, please ensure that there are straight pipe sections before and after the valve(Fig.2)