BINCIKE

BINCIKE  BINCIKE

BINCIKE  BINCIKE

BINCIKE

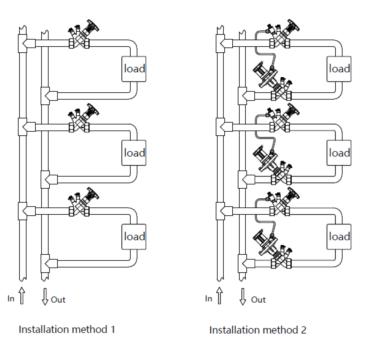

An yi amfani da shi don sarrafa bututun bututun da aka riga aka saita, ana amfani da wannan jerin samfuran galibi don magance matsalar rashin daidaituwar hydraulic a cikin watsa ruwa da hanyar rarraba ruwa.Dangane da tsarin tsarin, an ƙaddara cewa ruwan reshe yana dawwama a ƙarƙashin yanayin buɗewa daban-daban da bambance-bambancen matsa lamba.

Bawul ɗin daidaitawa na KMF yana ba da ingantaccen aikin hydronic a cikin kewayon aikace-aikace masu ban sha'awa.Mafi dacewa don amfani a gefe na biyu a tsarin dumama da sanyaya, da tsarin famfo ruwa.

| DN | Saukewa: DN15-DN50 | Saukewa: DN50-DN300 |

| Jiki | Brass | Nodular simintin ƙarfe |

| Hatimi | EPDM | EPDM |

| Spool | Brass | Brass |

| Matsakaici | Ruwan zafi mai ƙarancin zafi, ruwan zafi mai matsakaici, ruwan sanyi, ruwa tare da daskarewa Shawarwari: Maganin ruwa |

| Matsakaicin zafin jiki | -10 ~ 110 ℃ |

| Babban darajar PN | PN16 |

| Lambar samfur | DN | Haɗin kai | PN | L | H |  | |

| 6067.15 | 15 | 1/2 in | Zaren ciki (BSP) | PN16 | 80 | 114 | |

| 6067.20 | 20 | 3/4 in | 85 | 116 | |||

| 6067.25 | 25 | 1 inci | 98 | 119 | |||

| 6067.32 | 32 | 11/4 in | 110 | 136 | |||

| 6067.40 | 40 | 11/2 in | 120 | 138 | |||

| 6067.50 | 50 | 2 in | 150 | 148 | |||

| 6068.65 | 65 | Flanged (ISO7005-2 / GB 17241.6) | 290 | 285 |  | ||

| 6068.80 | 80 | 310 | 324 | ||||

| 6068.100 | 100 | 350 | 355 | ||||

| 6068.125 | 125 | 400 | 410 | ||||

| 6068.150 | 150 | 480 | 477 | ||||

| 6068.200 | 200 | 600 | 613 | ||||

| 6068.250 | 250 | 730 | 740 | ||||

| 6068.300 | 300 | 850 | 828 | ||||

| 6068.350 | 350 | 980 | 970 | ||||

| 6068.400 | 400 | 1100 | 1100 | ||||

| Lambar samfur | DN | Babu juyi | ||||||||||

| 0.25 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | ||

| 6067.15 | DN15 | 0.21 | 0.35 | 0.48 | 0.55 | 0.74 | 0.97 | 1.36 | 1.72 | 2.06 | 2.36 | 2.72 |

| 6067.20 | DN20 | 0.34 | 0.51 | 0.71 | 0.92 | 1.15 | 1.35 | 1.62 | 2.05 | 2.60 | 3.13 | 3.67 |

| 6067.25 | DN25 | 0.55 | 0.94 | 1.54 | 2.07 | 2.57 | 3.10 | 3.70 | 4.43 | 5.5 | 5.94 | 6.73 |

| 6067.32 | DN32 | 0.59 | 1.04 | 2.05 | 2.91 | 4.03 | 5.10 | 6.02 | 6.86 | 7.65 | 8.63 | 9.70 |

| 6067.40 | DN40 | 1.22 | 2.65 | 4.14 | 5.75 | 7.35 | 8.72 | 10.03 | 11.22 | 12.35 | 13.83 | 15.25 |

| 6067.50 | DN50 | - | 2.70 | 5.05 | 7.15 | 9.15 | 11.66 | 14.22 | 16.35 | 18.52 | 20.72 | 22.95 |

| Lambar samfur | DN | Babu juyi | ||||||||||

| 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | |||

| 6067.15 | DN15 | 3.05 | 3.42 | 3.70 | 3.90 | - | - | - | - | - | - | - |

| 6067.20 | DN20 | 4.25 | 4.90 | 5.45 | 5.70 | - | - | - | - | - | - | - |

| 6067.25 | DN25 | 7.33 | 7.90 | 8.42 | 8.90 | - | - | - | - | - | - | - |

| 6067.32 | DN32 | 10.72 | 11.72 | 12.80 | 13.90 | 15.04 | 16.14 | 17.15 | 18.16 | 18.90 | 19.42 | - |

| 6067.40 | DN40 | 17.36 | 19.44 | 20.96 | 22.43 | 23.62 | 24.80 | 25.42 | 26.07 | 26.82 | 27.50 | - |

| 6067.50 | DN50 | 24.52 | 26.07 | 27.74 | 29.40 | 31.12 | 32.75 | 34.72 | 36.70 | 37.96 | 38.80 | - |

| Babu juyi | Lambar samfur | |||||||||

| 6068.65 | 6068.80 | 6068.100 | 6068.125 | 6068.150 | 6068.200 | 6068.250 | 6068.300 | 6068.350 | 6068.400 | |

| DN 65 | DN 80 | Farashin DN100 | Farashin DN125 | Farashin DN150 | DN 200 | Farashin DN250 | DN 300 | Farashin DN350 | Farashin DN400 | |

| 0.5 | 1.8 | 2 | 2.6 | 5.4 | 6.6 | - | - | - | - | - |

| 1 | 3.4 | 4 | 6 | 10.4 | 12 | - | - | - | - | - |

| 1.5 | 4.8 | 6 | 9 | 15.4 | 22 | - | - | - | - | - |

| 2 | 6.6 | 8 | 11.5 | 21.5 | 40 | 40 | 90 | - | - | - |

| 2.5 | 9.3 | 11 | 16 | 27 | 65 | 50 | 110 | - | - | - |

| 3 | 16.3 | 14 | 26 | 36 | 100 | 65 | 140 | 150 | 109 | 125 |

| 3.5 | 25.5 | 19.6 | 44 | 55 | 135 | 90 | 195 | 230 | 129 | 148 |

| 4 | 35.4 | 29 | 63 | 83 | 169 | 120 | 255 | 300 | 148 | 171 |

| 4.5 | 44.5 | 41 | 80 | 114 | 207 | 165 | 320 | 370 | 170 | 208 |

| 5 | 52 | 55 | 98 | 141 | 242 | 225 | 385 | 450 | 207 | 264 |

| 5.5 | 60.6 | 68 | 115 | 167 | 279 | 285 | 445 | 535 | 254 | 326 |

| 6 | 66 | 80 | 132 | 197 | 312 | 340 | 500 | 620 | 302 | 386 |

| 6.5 | 73 | 92 | 145 | 220 | 340 | 400 | 545 | 690 | 352 | 449 |

| 7 | 77 | 103 | 159 | 249 | 367 | 435 | 590 | 750 | 404 | 515 |

| 7.5 | 80.6 | 113 | 175 | 276 | 391 | 470 | 660 | 815 | 471 | 590 |

| 8 | 85 | 120 | 190 | 300 | 420 | 515 | 725 | 890 | 556 | 680 |

| 9 | - | - | - | - | - | 595 | 820 | 970 | 784 | 890 |

| 10 | - | - | - | - | - | 650 | 940 | 1040 | 957 | 1140 |

| 11 | - | - | - | - | - | 710 | 1050 | 1120 | 1100 | 1250 |

| 12 | - | - | - | - | - | 765 | 1185 | 1200 | 1260 | 1400 |

| 13 | - | - | - | - | - | - | - | 1320 | 1420 | 1560 |

| 14 | - | - | - | - | - | - | - | 1370 | 1610 | 1730 |

| 15 | - | - | - | - | - | - | - | 1400 | 1760 | 1940 |

| 16 | - | - | - | - | - | - | - | 1450 | 1870 | 2140 |

| 17 | - | - | - | - | - | - | - | - | 1960 | 2280 |

| 18 | - | - | - | - | - | - | - | - | 2040 | 2410 |

| 19 | - | - | - | - | - | - | - | - | 2130 | 2530 |

| 20 | - | - | - | - | - | - | - | - | 2200 | 2630 |

| 21 | - | - | - | - | - | - | - | - | - | 2710 |

| 22 | - | - | - | - | - | - | - | - | - | 2780 |

Matsayin sifili an daidaita shi kuma dole ne a canza shi.

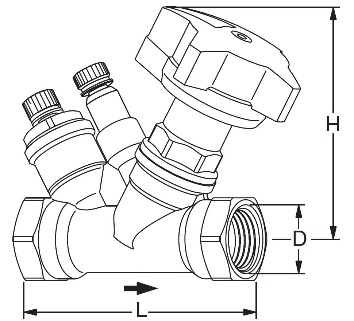

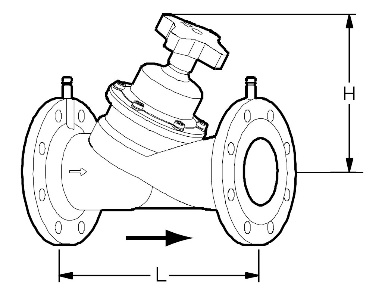

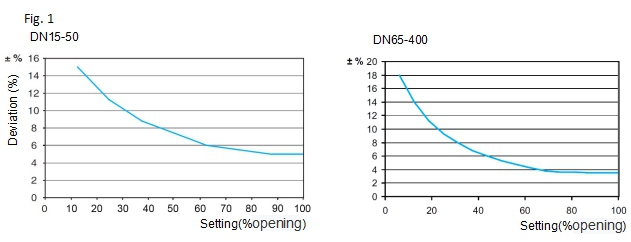

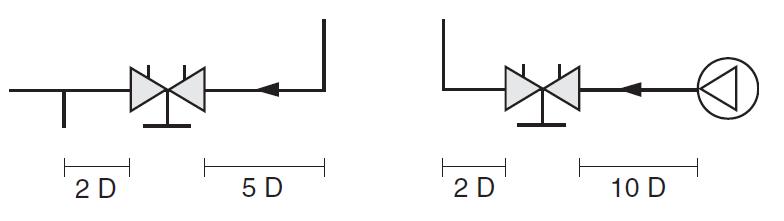

Hanya (Fig. 1) yana aiki don bawuloli tare da kayan aikin bututu na yau da kullun (Fig.2).Gwada kuma don guje wa hawa famfo da famfo, nan da nan kafin bawul.

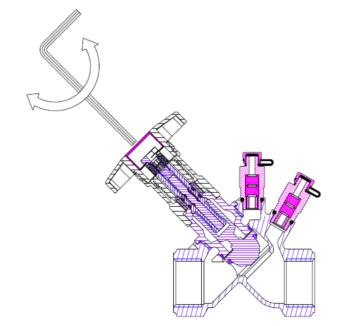

Hoto.2

Daidaita ma'auni na ƙafar hannu bisa ga buƙatun ƙira.

Ya kamata a shigar da na'urori masu ƙyalli a cikin bututun tsarin, kuma tsarin zai iya ƙunsar iska, wanda zai iya haifar da toshewar kafofin watsa labaru, gazawar aikin daidaitawa, ko yawan hayaniya;

Ana ba da shawarar ƙara tacewa ko tsaftace bututun a mashigar ruwa na bawul don guje wa manyan ɓangarorin ƙazanta da ke toshe ɓangaren sarrafa bawul;

Kula da kariyar ramin ganowa, idan an taɓa shi ko kuma ya lalace, zai haifar da zubewa ko kulawa mai wahala a nan gaba.

Daidaita ma'auni na ƙafar hannu bisa ga buƙatun ƙira.

Wannan bawul ɗin yana da aikin saita madaidaicin ƙimar kwarara.Yi amfani da maƙarƙashiya hexagonal don jujjuya matsakaicin iyakar buɗewar core kusa da agogo, ta yadda matsakaicin buɗewar bawul ɗin zai iya iyakancewa, kuma kulawar tsarin na gaba ba zai buƙaci gyara ba.

Ana iya amfani da bawul ɗin ma'auni kaɗai don sarrafa tsarin tsarin, ko kuma ana iya amfani dashi tare da bawul ɗin matsa lamba daban-daban.Lokacin da aka shigar da bawul ɗin, dole ne jagorancin kwararar ruwa ya kasance daidai da jagorancin kibiya akan bawul.Domin tabbatar da daidaiton ma'auni, da fatan za a tabbatar da cewa akwai sassan bututu madaidaiciya kafin da bayan bawul (Fig.2)